Air compressor manufacturer lost thousands of dollars on repairs.

A German manufacturer of industrial air compressors built its reputation on durability. Their systems had a lifespan of up to 30 years and came with 15-year service contracts, but frequent repairs during these long agreements became a growing concern.

The main cause of frequent issues was zero visibility into maintenance. Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site, leading to high costs. To cut support expenses, they needed to digitize the core of their machines. But with systems spread across factories worldwide, how could they gain full visibility?

We nurture a culture of meaningful partnership in a market that got used to short-term collabs and untapped potential.

Discover new opportunities with Yalantis

They set 3 goals:

- Build industrial IoT devices that could run autonomously in extreme, hazardous environments

- Provide full visibility into machine state for both their team and their clients

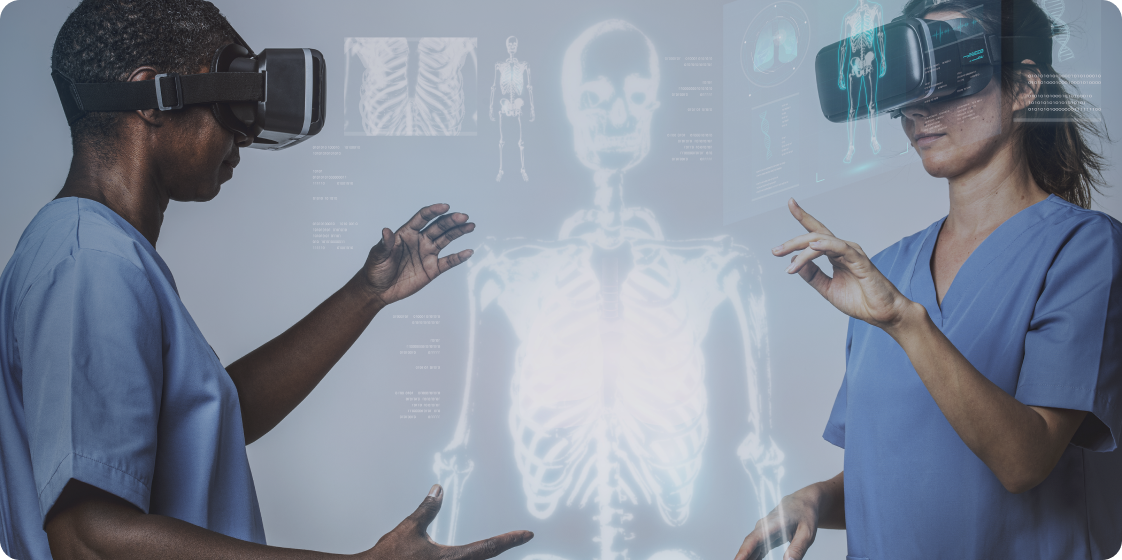

- Enable predictive maintenance with AI and ML

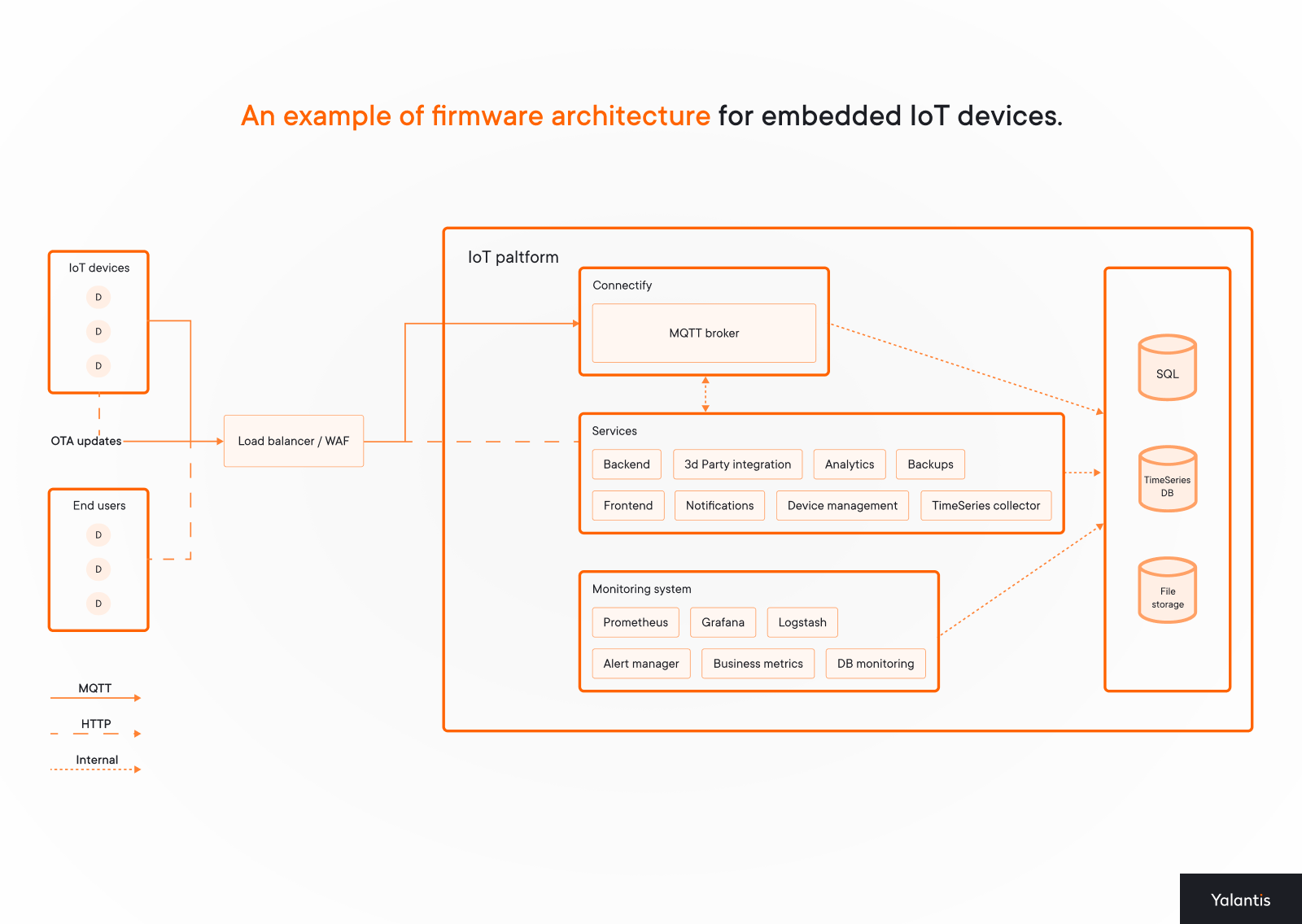

Because these systems operate in potentially flammable environments, devices had to safely monitor magnetic fields, temperature, and vibration while complying with strict international explosion-proof standards.

Off-the-shelf devices didn’t meet all requirements, and those that nearly fit were too expensive. That’s when the company partnered with Yalantis to design custom hardware, connect it to the cloud, and power it with an AI-driven predictive maintenance system.

Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site

The main cause of frequent issues was zero visibility into maintenance. Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site, leading to high costs. To cut support expenses, they needed to digitize the core of their machines. But with systems spread across factories worldwide, how could they gain full visibility?

A German manufacturer of industrial air compressors built its reputation on durability. Their systems had a lifespan of up to 30 years and came with 15-year service contracts, but frequent repairs during these long agreements became a growing concern.

A German manufacturer of industrial air compressors built its reputation on durability. Their systems had a lifespan of up to 30 years and came with 15-year service contracts, but frequent repairs during these long agreements became a growing concern.

The main cause of frequent issues was zero visibility into maintenance.

A German manufacturer of industrial air compressors built its reputation on durability. Their systems had a lifespan of up to 30 years and came with 15-year service contracts, but frequent repairs during these long agreements became a growing concern.

The main cause of frequent issues was zero visibility into maintenance. Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site, leading to high costs. To cut support expenses, they needed to digitize the core of their machines. But with systems spread across factories worldwide, how could they gain full visibility?

The main cause of frequent issues was zero visibility into maintenance. Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site, leading to high costs. To cut support expenses, they needed to digitize the core of their machines. But with systems spread across factories worldwide, how could they gain full visibility?

The main cause of frequent issues was zero visibility into maintenance. Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site, leading to high costs. To cut support expenses, they needed to digitize the core of their machines. But with systems spread across factories worldwide, how could they gain full visibility?

The main cause of frequent issues was zero visibility into maintenance.

A German manufacturer of industrial air compressors built its reputation on durability. Their systems had a lifespan of up to 30 years and came with 15-year service contracts, but frequent repairs during these long agreements became a growing concern.

The main cause of frequent issues was zero visibility into maintenance. Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site, leading to high costs. To cut support expenses, they needed to digitize the core of their machines. But with systems spread across factories worldwide, how could they gain full visibility?

They set 3 goals:

- Build industrial IoT devices that could run autonomously in extreme, hazardous environments

- Provide full visibility into machine state for both their team and their clients

- Enable predictive maintenance with AI and ML

- Lorem ipsum dolor

A German manufacturer of industrial air compressors built its reputation on durability. Their systems had a lifespan of up to 30 years and came with 15-year service contracts, but frequent repairs during these long agreements became a growing concern.

The main cause of frequent issues was zero visibility into maintenance. Clients missed routine fixes, small problems escalated, and the company had to send technicians on-site, leading to high costs. To cut support expenses, they needed to digitize the core of their machines. But with systems spread across factories worldwide, how could they gain full visibility?

FAQ

How does your software developer company ensure product security?

How does your software developer company ensure product security? How does your software developer company ensure product security? How does your software developer company ensure product security?

How does your software developer company ensure product security?

How does your software developer company ensure product security? How does your software developer company ensure product security? How does your software developer company ensure product security?